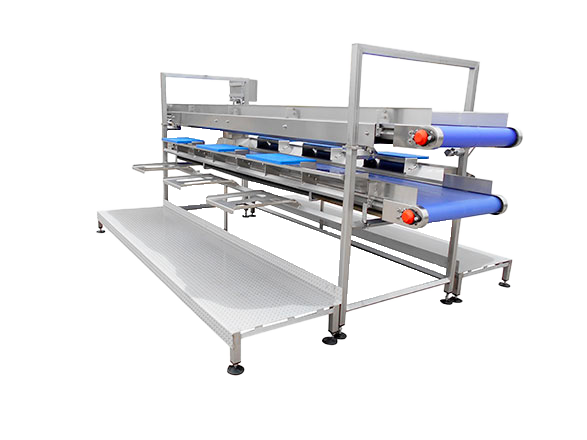

Roller brusher mod. Everest

It is a solution created to clean potatoes, carrots, onions, red turnips, celeriac, and is adjustable to obtain a smooth and uniform finish for each type of product. Available in various sizes and configurations as needed.

The main features are:

- Uniform brushing and high yield.

- Simple control panel management, affecting the speed of individual components.

- Accessibility to various parts for cleaning and maintenance.

- Long life of rollers and ease of changing them.

- Reduced water consumption.

- Durable and reliable construction.

Product

Processing

Brushing

Machine features

-

Capacity:2000/3000 kg/h

To complete the line

-

Bins tipper mod. London

Solutions for filling the supply bunker of a line using standard BINS or other large containers, with adjustable product outlet with a sluice gate. Both fixed and mobile solutions are available, for use on more than one line depending on necessity.Without treatment,

Canned food and preserves,

Ready to cook,

Ready to eat, fresh cut,

Ready to heat

View product

-

Preparation/trim table solutions

Ergonomic and functional solutions for the optimization of cleaning operations of products. Normally equipped with inlet belt for the product to be clean and output for clear product, may have a third ribbon for scrap. Each station has a PVC board for the processing of the product and a slide for scraps. It is always possible to customize the solutions according to the needs.Without treatment,

Canned food and preserves,

Ready to cook,

Ready to eat, fresh cut,

Ready to heat

View product

-

Working table for pineapples mod. Fructus

Robust support bench for semi-automatic machines used in the manufacture of pineapples and other fruits, which can accommodate up to 6 stations.Ready to cook,

Ready to eat, fresh cut

View product