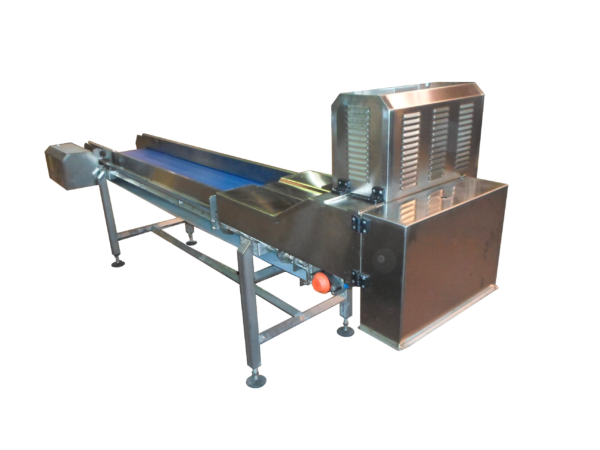

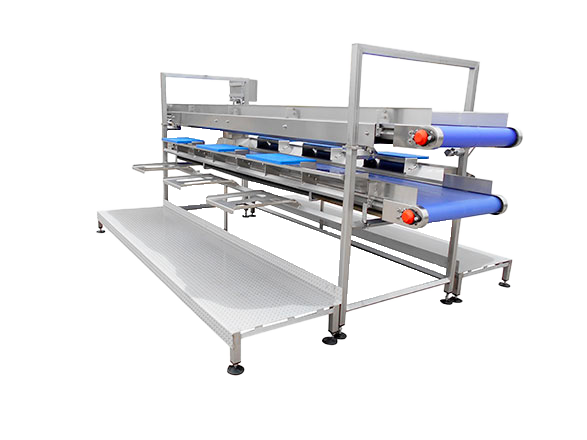

Roller sorting conveyor mod. Padova

Special solution designed to run the products during the advancement, allowing operators to control the entire surface, as happens for potatoes after peeling.

The main features are:

- From 2 to 32 operators.

- Several possible configurations.

- Rollers available in different materials.

- Integration with lateral sorting stations.

Product

Processing

Control

Machine features

-

Capacity:Based on the product being processed and

To complete the line

-

Rotary disc slicer mod. Zeus

This cutter for salads and leaf products, was born to be fed directly by a conveyor belt. It can adapt to many products thanks to the numerous cutting heads available.Without treatment,

Ready to eat, fresh cut

View product

-

Bins tipper mod. London

Solutions for filling the supply bunker of a line using standard BINS or other large containers, with adjustable product outlet with a sluice gate. Both fixed and mobile solutions are available, for use on more than one line depending on necessity.Without treatment,

Canned food and preserves,

Ready to cook,

Ready to eat, fresh cut,

Ready to heat

View product

-

Preparation/trim table solutions

Ergonomic and functional solutions for the optimization of cleaning operations of products. Normally equipped with inlet belt for the product to be clean and output for clear product, may have a third ribbon for scrap. Each station has a PVC board for the processing of the product and a slide for scraps. It is always possible to customize the solutions according to the needs.Without treatment,

Canned food and preserves,

Ready to cook,

Ready to eat, fresh cut,

Ready to heat

View product