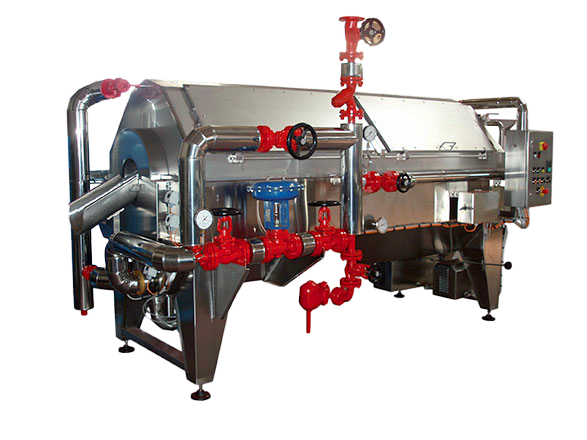

Rotary drum blancher mod. Palladio

Solution designed for the cooking of floating and non-floating products, dipping them partially for cooking at atmospheric pressure. The heating is done by putting the steam into the water. The control panel allows to obtain the best results.

The main features are:

- Improved product quality.

- Improved performance.

- Facilitated sanitization.

- Increased efficiency.

- Reduced running costs.

- Available in cooker or cooler configuration.

- Control system for quick product changes.

- Available in different sizes

- Automatic temperature control.

Product

Processing

Cooking

Machine features

-

Capacity:2/5 tons/h depending on the product

To complete the line

-

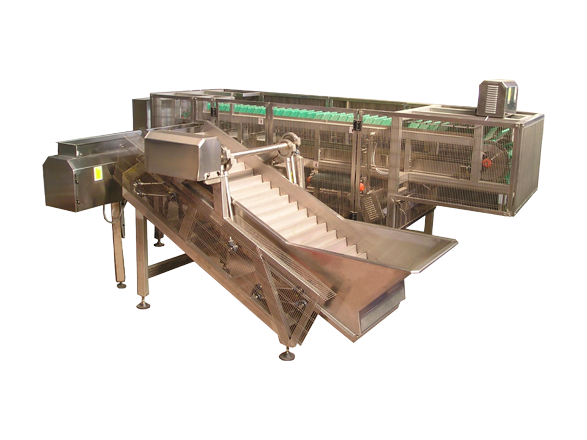

Automatic top & tail / segment cutter mod. Robespierre

This machine was created to remove the head and tail of oblong shaped vegetables such as carrots and eggplant. In addition can be equipped with a battery of transverse blades for the division of products into parts. It can be used in line.Without treatment,

Canned food and preserves,

Ready to cook,

Ready to eat, fresh cut,

Ready to heat

View product

-

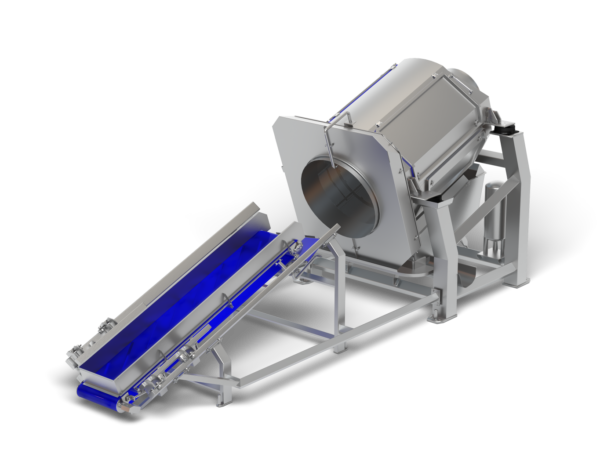

Automatic electric spin dryer mod. Vortex-H

This centrifuge solution is an alternative to the use of the drying tunnel. The fixed oblique basket has an extremely homogeneous loading that allows to reach extreme drying performance without damaging the most delicate products.Ready to cook,

Ready to eat, fresh cut

View product

-

Decorer mod. Titano

This automatic machine was created to detour, tap and cut into parts different types of products like coliflower and cabbage. It works continuously and is powered manually. Is available in the version with the workstation for the removal of leaves cauliflower leaves and with two parallel work lanes.Canned food and preserves,

Ready to cook,

Ready to eat, fresh cut,

Ready to heat

View product