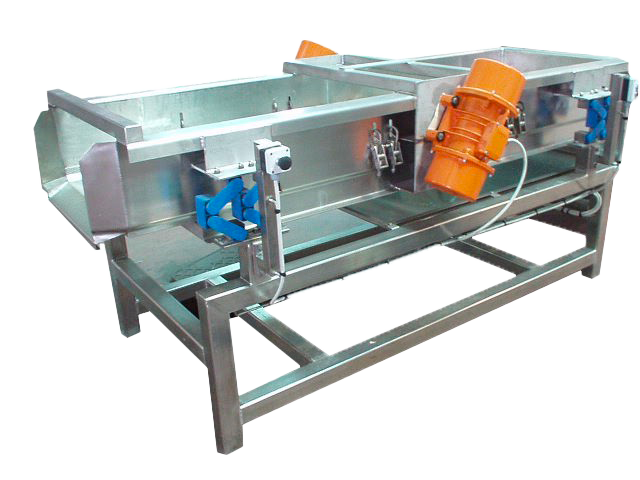

Vibrating table mod. Cortina

It is the solution that allows the product to be collected and distributed horizontally, to best feed solutions that require it, such as optical sorters or drying tunnels in production lines.

The main features are:

- Hygienic design

- Fully adaptable to the needs for inclination, type of feeding, loading hoppers and exit sides.

Product

Processing

Transport

Machine features

-

Dimensions:850x1000 mmCapacity:according to the product

-

Dimensions:1000x1200 mmCapacity:according to the product

-

Dimensions:1200x1800 mmCapacity:according to the product

-

Dimensions:1200x2500 mmCapacity:Dimensions:

-

Dimensions:1400x3000 mmCapacity:Dimensions:

To complete the line

-

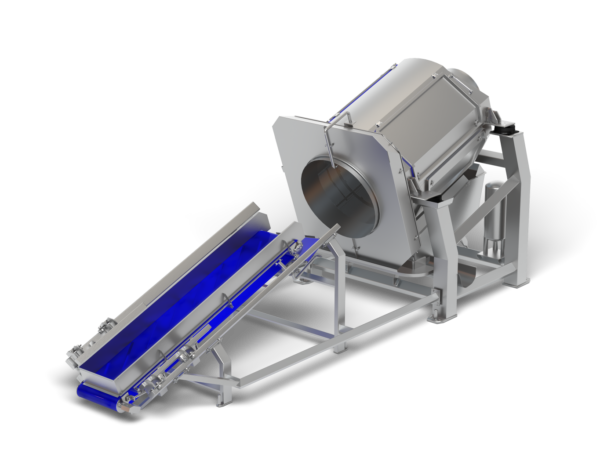

Automatic electric spin dryer mod. Vortex-H

This centrifuge solution is an alternative to the use of the drying tunnel. The fixed oblique basket has an extremely homogeneous loading that allows to reach extreme drying performance without damaging the most delicate products.Ready to cook,

Ready to eat, fresh cut

View product

-

Automatic spiralizer mod. Streamer

Special solution for spiral cutting of products such as carrots, zucchini, cucumbers, broccoli stalk and squash violina, to obtain spaghetti baskets, noodles or simply the helical cut of the product. Also available in a compact version.Ready to cook,

Ready to eat, fresh cut

View product

-

Slicer for blanched mushrooms mod. Hydra

Simple machine for cutting cooked mushrooms with water transport, equipped with a head of cutting.Canned food and preserves,

Ready to heat

View product