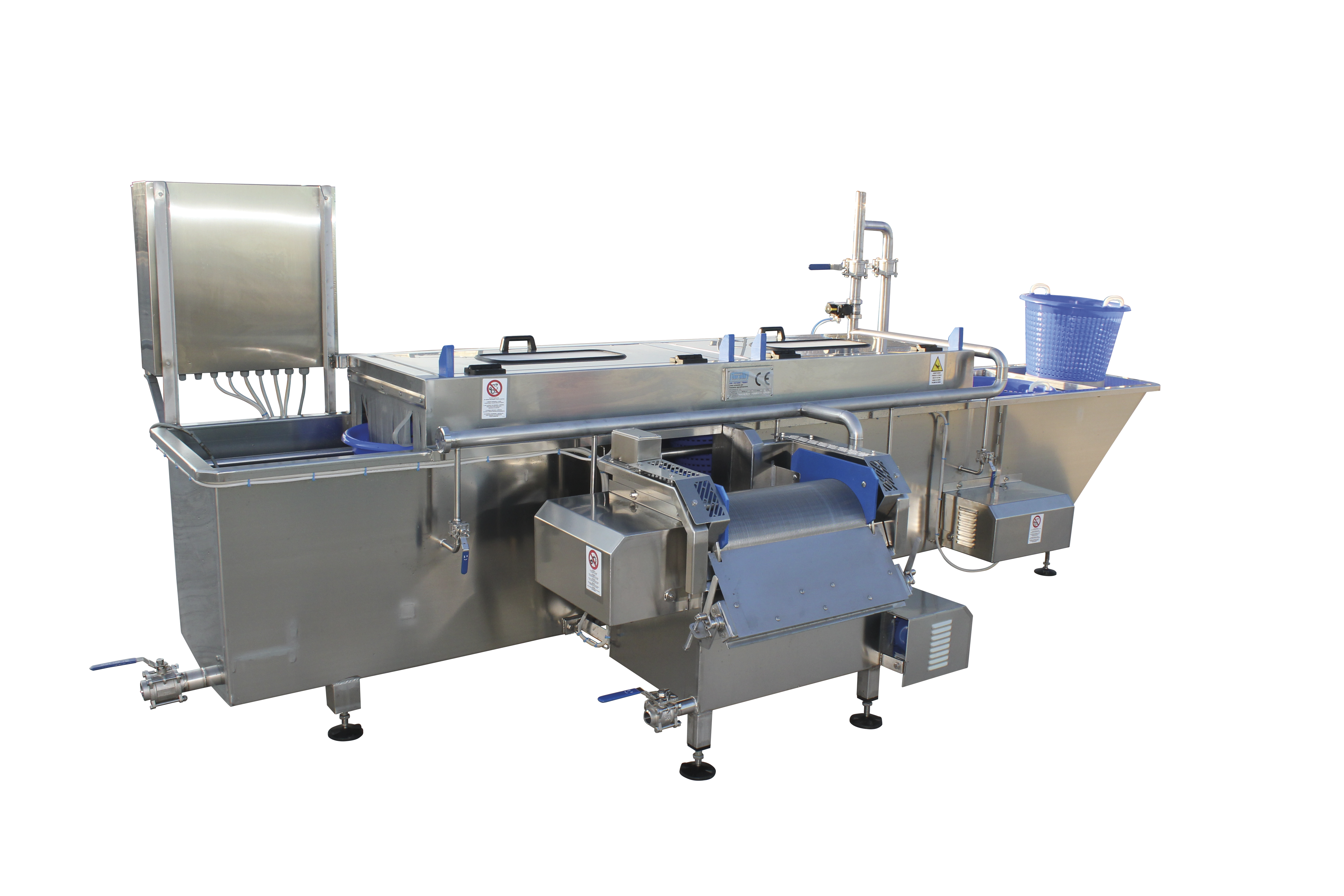

Continuous in-basket washer mod. Portofino

This solution is suitable for washing, treatment and disinfection of different types of products, uses baskets in continuous cycle, allowing flexible and efficient use of solutions and washing liquids.

The main features are:

- Washing of floating and non-floating products .

- Efficient surface cleaning of fruits and vegetables.

- Washing time and adjustable mumbling level to achieve a high degree of flexibility.

- Compact unit that can be installed in a small space.

- Customizable to customer needs.

Product

Processing

Washing

Machine features

-

Capacity:5/6 baskets/minute.

To complete the line

-

Automatic top & tail / segment cutter mod. Robespierre

This machine was created to remove the head and tail of oblong shaped vegetables such as carrots and eggplant. In addition can be equipped with a battery of transverse blades for the division of products into parts. It can be used in line.Without treatment,

Canned food and preserves,

Ready to cook,

Ready to eat, fresh cut,

Ready to heat

View product

-

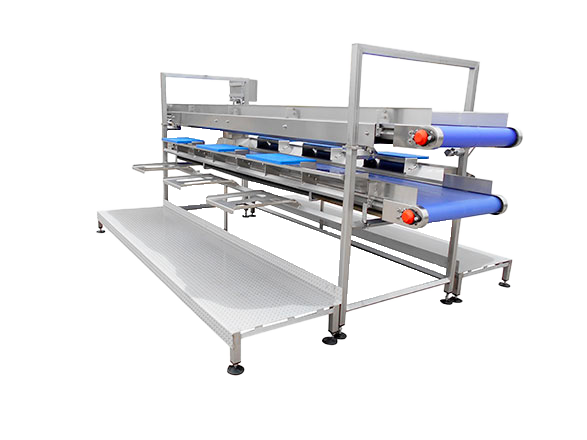

Preparation/trim table solutions

Ergonomic and functional solutions for the optimization of cleaning operations of products. Normally equipped with inlet belt for the product to be clean and output for clear product, may have a third ribbon for scrap. Each station has a PVC board for the processing of the product and a slide for scraps. It is always possible to customize the solutions according to the needs.Without treatment,

Canned food and preserves,

Ready to cook,

Ready to eat, fresh cut,

Ready to heat

View product

-

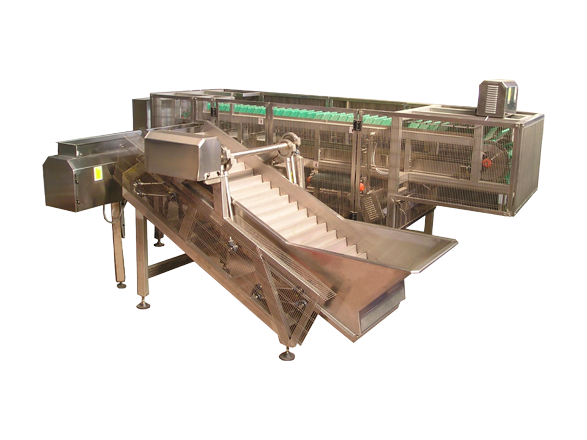

Storage bunker with bins tipper

Solution created for the constant feeding of a processing line for carrots and others, equipped with a sluice gate to regulate the quantity of the product introduced, and powered using standard BINS or other large containers.View productWithout treatment,

Canned food and preserves,

Ready to cook,

Ready to eat, fresh cut,

Ready to heat