We cannot discuss sustainable development without addressing the issue of food security and the necessary actions needed to ensure it.

The 2030 Agenda for sustainable development, with its broad program divided into 17 global macro-objectives that will put the world on a course of economic, social, and environmental sustainability.

Fueled by the experience of the health crisis of recent years, Turatti has considered health and hygiene as a collective aspect of good daily and individual practices. There is now a path mapped out to which we must all contribute.

A path in which the agri-food sector is in the foreground to guarantee healthier food for more people, reduce poverty, and hunger through an innovative processing system that reduces the consumption of consumables.

How food safety helps sustainability

According to FAO, food safety is defined as a “discipline, process or action, based on science, that prevents contamination of food with substances that could harm health.”

Food, one of the basic needs of man, can contribute to alleviating poverty and social hardship only when it is available in adequate quantities throughout the year. Preserving its nutritional characteristics while guaranteeing its safety are one of the key challenges.

Achieving such a result can only be achieved if each operator in the supply chain, from producer to consumer, is actively involved and adopts all the useful practices to keep food uncontaminated and safe to eat. A complete paradigm shift in processing.

Hygienic Design’s principles to improve nutrition

One crucial principle in Hygienic Design is to allow effective cleaning and sanitizing operations, while reducing the use of chemicals during processing.

In particular, Hygienic Design aims to design equipment and work environments that comply with high standards of hygiene and quality. According to international guidelines and regulations, including the Machinery Directive 2006/42/EG, the EHEDG standard, ISO and 3-A.

Compatibility with hygiene directives and safety requirements is actually an advantage that goes far beyond compliance. One of the key benefits for a company is the quality of the end product and longer shelf life. Having a premium product not only protects a company’s reputation in a highly competitive market, but the new process being spearheaded by Turatti can:

- lower maintenance and cleaning costs;

- less use of sanitizing products;

- lower unplanned downtime;

- reduce consumables

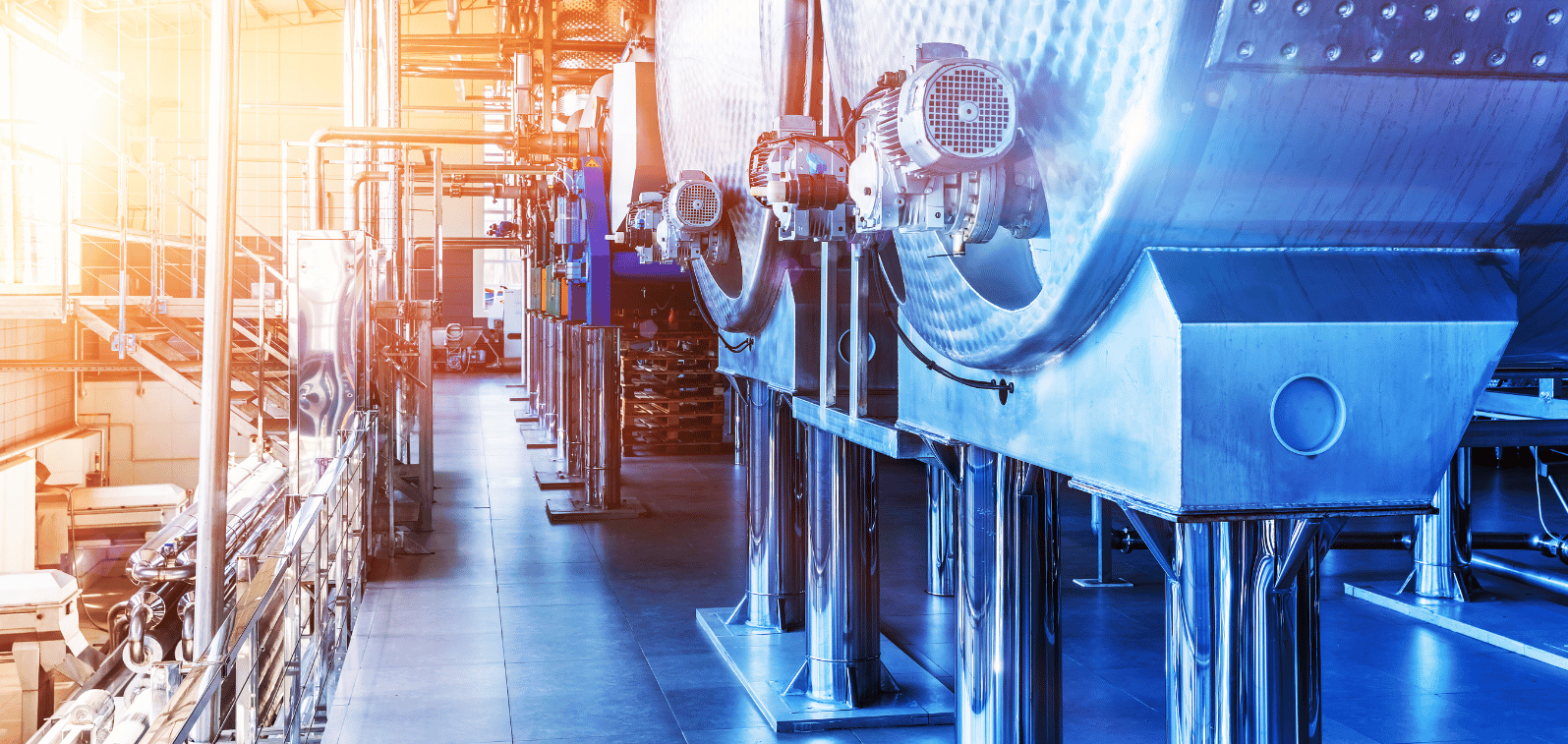

Turatti’s Answer

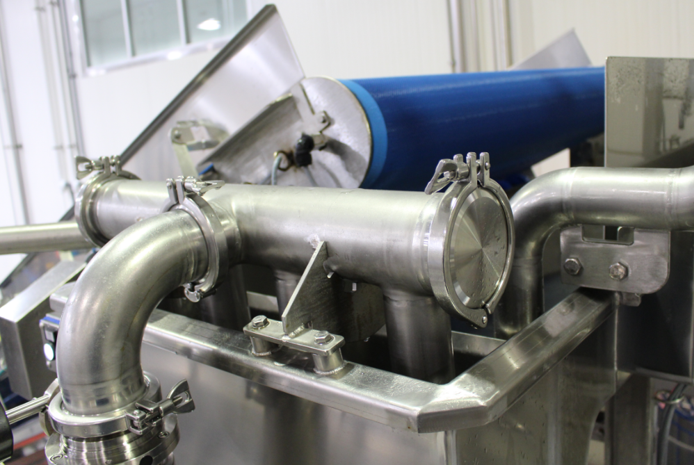

Turatti’s technological research in the field of Hygienic Design has led to the development of important features including:

- open folded profile structures, which replaces the old tubular design: with complete cleanability and no hygienic risk compared to tubular frame;

- use of polished scotch-brite steel instead of the 2B + micro-shot peening combination: All surfaces are smooth and do not have rough surfaces that can house bacteria;

- all surfaces are inclined or angled to avoid water stagnation;

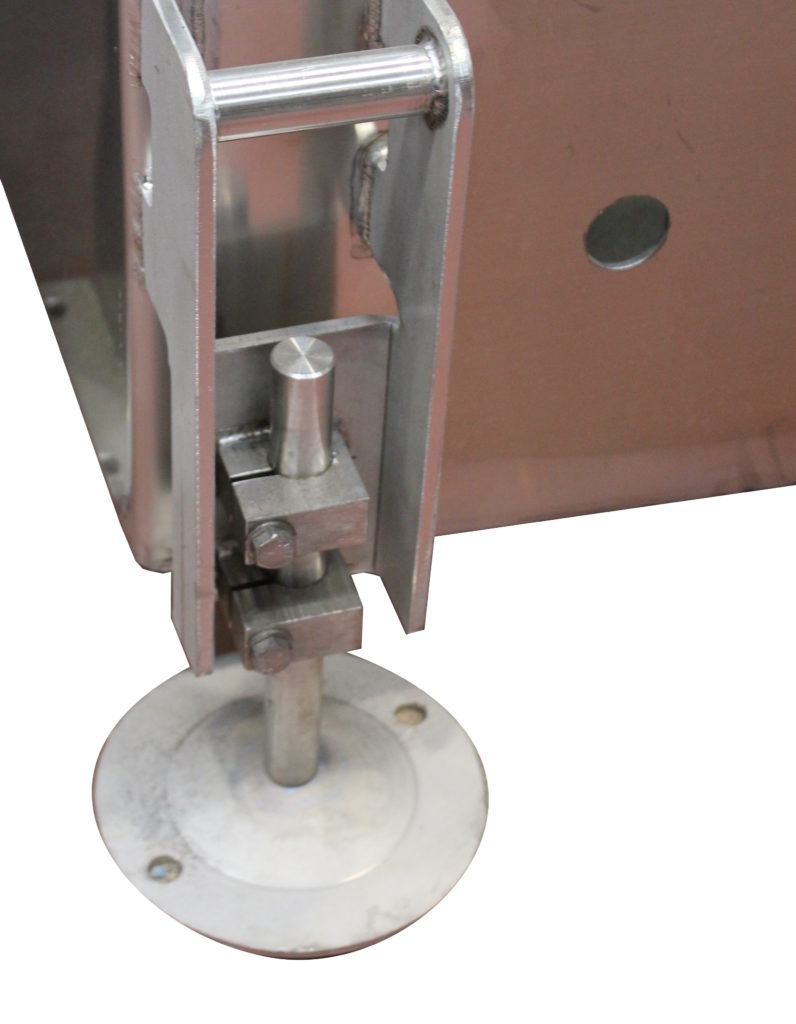

- absence of dead zones/dead spots, pinch points, which guarantees full accessibility for cleaning (openable fans, quick release belts, etc.);

- attention to detail that include: spacers to reduce contact surfaces, adjustable sanitary feet, absence of exposed threads, and absence of pinch points